Micro Commercial Components (MCC) Battery Management System (BMS)

MCC Battery Management System (BMS) Solutions deliver the precision, safety, and efficiency required to support today’s electric vehicles (EVs). As EV adoption accelerates and battery performance becomes a critical differentiator, MCC components enable smarter energy control, longer battery life, and reliable system operation under demanding real-world conditions.MCC’s advanced portfolio supports the development of efficient and dependable BMS designs, paving the way for longer-lasting, safer, and smarter electric vehicles. Above all, MCC-enabled BMS designs help prevent catastrophic failures such as short circuits or thermal runaway, ensuring safety without sacrificing performance.

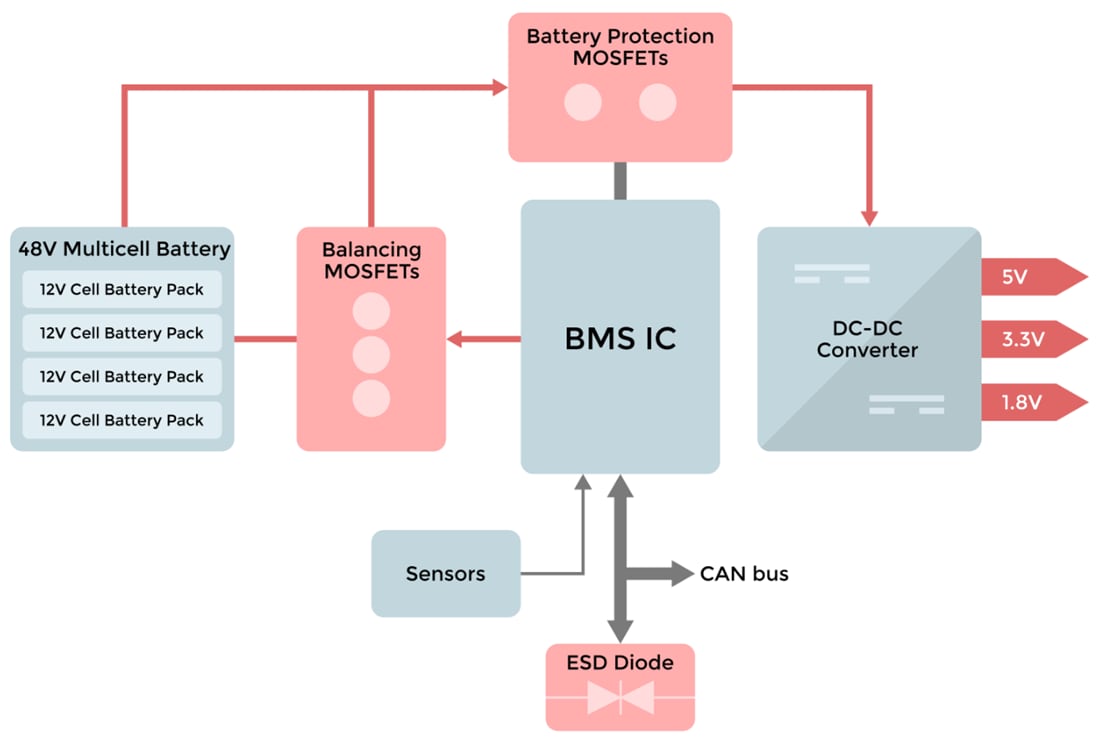

At the core of every EV lies its battery, and managing it effectively is vital to both performance and safety. MCC supports the intelligent design of BMS architectures that continuously monitor and optimize battery health in real time. From extending the range to preventing thermal events, MCC components help build the control backbone behind modern EV battery packs.

Features

- Real-time cell balancing for peak performance

- Charge termination upon full capacity

- Safe system shutdown during thermal anomalies

- Fault detection and alert communication

- State-of-charge (SOC) reporting for accurate range estimation

- State-of-health (SOH) tracking for long-term battery insights

Design Requirements

- MCC’s automotive-grade semiconductors are built to meet the critical demands of BMS applications, enabling efficiency, reliability, and robust protection

- Charge/discharge management - Avoid harmful overcharging, deep discharging, and current surges

- Efficiency optimization - Support a higher range and lower energy loss through minimal conduction resistance

- ESD and surge protection - Shield sensitive circuitry from damaging transients

- High current capability - Deliver stable power during fast charging or acceleration

- Fast switching performance - Improve throughput with reduced switching losses

- Thermal reliability - Operate in elevated temperatures without degradation

- Low on-resistance - Reduce heat buildup and extend system longevity

- Low reverse recovery time (Trr) - Minimize voltage spikes during switching

- Automotive compliance - AEC-Q101 and ISO 26262 qualified for safety and reliability

Videos

Block Diagram

Veröffentlichungsdatum: 2025-06-17

| Aktualisiert: 2025-06-26